- Overview

- Customer Review

- Purchasing guide

- Delivery

Screen Sheet |

|

1. Wear resistant, long service life, saving production cost.

2. Even and standardized screen hole, ensuring your product good quality.

3. High porosity, bringing you high output and high benefits, besides good quality.

4. Compact and covenient connection of screen sieve, no leakage of materials and labor&time saved.

5. Thanks to the moderate firmness and softness, in the processing, screen is not easy to break and distort.

6. Screen sieve and hole feature even distribution with prismatic arrangement, good to raise sifting efficiency.

7. Raw materials are strictly examined to ensure screen operational performance.

8. Pretty appearance,smooth screen sheet, pure hue,no breakage,burring,underfilled, mixed material.

9. Reasonable price, considerate after-sales service, let you be rest assured and without worry.

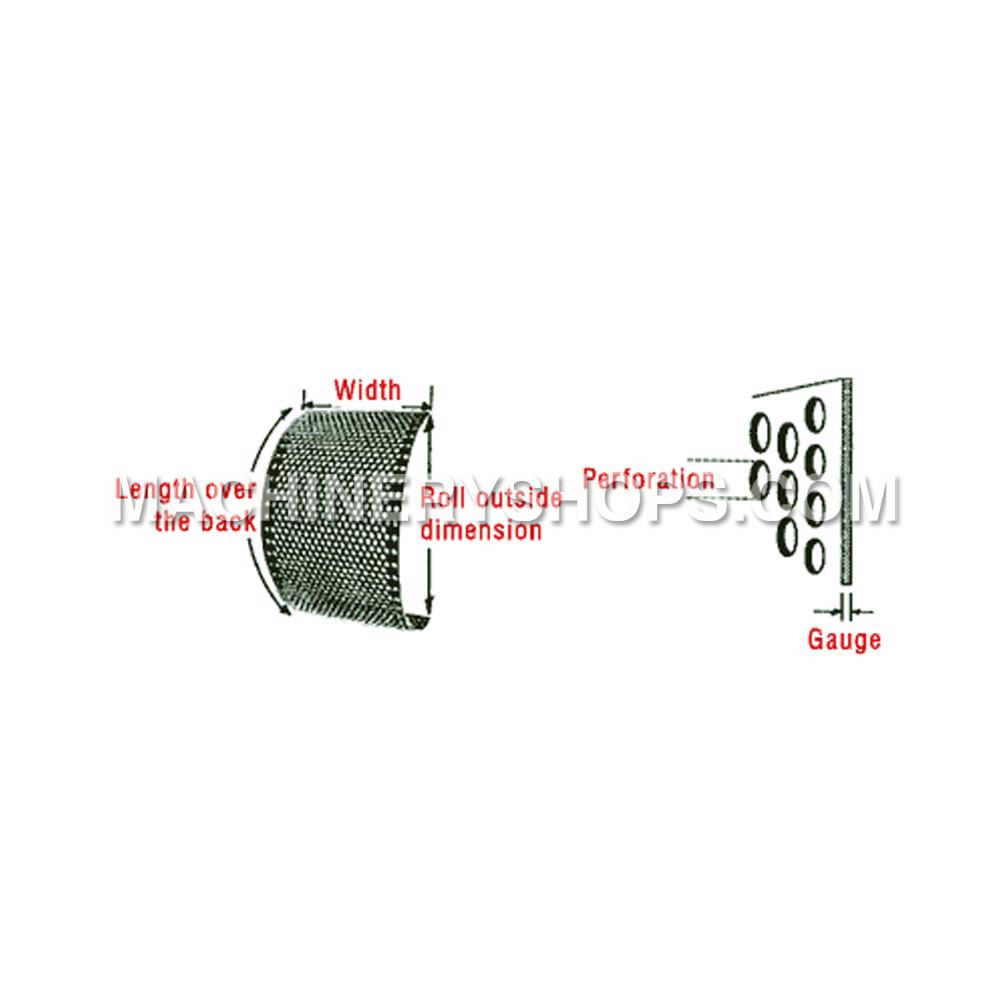

Screen sieve is a main part in controling ground product granularity and also one of the main wearing parts of hammer mill. Its type, shape,wrap angle and porosity have a large impact on grinding and sifting efficiency.

Screen classification and specification Screen sheet used in hammermill can be divided into cylindrical screen,conical screen and fish-scale screen etc.With the characteristics of simple structure and convenient producing, cylindrical screen is most widely used in the industry.

Single purpose machine,high porosity of screen,array hole more even, processing various kinds of aperture of screen, such as Ф0.2mm、Ф0.6mm、Ф0.8mm、Ф1.0mm、Ф1.2mm、Ф1.5mm、Ф2.0mm、Ф2.5mm、Ф3.0mm.

Hammer Mill Perforated Screens

Hammer mills screens are used inside a hammer mill to seperate particle sizes. Particle of small enough diameter that has been sucessfully grinded by the hammer mill passes through the screen and leaves the hammer mill with the aid of th pneumatic system.

Screen Design

The amount of open area in a hammer mill screen determines the particle size and grinding efficiency. The screen must be designed to maintain its integrity and provide the greatest amount of open area. Feed producers need to pay particular attention to the ratio of open screen area to horsepower. Not enough open area per horsepower results in the generation of heat. When the heat generated exceeds 44C to 46C (120-125F), capacity may be decreased as much as 50 percent.

The removal of sized material from a hammermill is a critical design feature. Proper output of material affects not only the efficiency of operation, but also particle size. When the correct ratio of screen area to horsepower is used and proper distance between hammers and screen face is maintained, most of the correctly sized particles will exit the screen in a timely manner.

Most newer hammermills are equipped with an air-assist system that draws air into the hammer mill with the product to be ground. Systems are designed to provide reduced pressure on the exit side of the screen to disrupt the fluidized bed of material on the face of the screen, thus allowing particles to exit through screen holes. Some full circle hammer mills are designed so the screen is in two pieces. It is possible to use a larger hole size on the upward arc of the hammers to further reduce the amount of material on the face of the screen.

About Muyang

Machineryshops.com is Muyang Group’s e-commerce site, where customers find it easier, faster and more covenient to know Muyang products, make inquiries, purchase products and obtain services, thus enhancing customers' market competitiveness.

Muyang Group has since its founding in 1967 grown into a prestigious global group corporation, whose sales and technical service network covers dozens of countries throughout the world. Muyang Group has technology research and development bases in Germany, China, Japan and USA and the most key parts of products are produced in Europe,Japan and USA with complete machine assembling and testing in some countries including China. Muyang Group’s activities cover design, development, fabrication, installation and integration solution of the machinery & engineering of the following industries such as feed manufacturing, bulk solids handling and storage, grain milling, environment protection, food processing, steel structure building as well as industrial automation.

2011 annual sales of Muyang Group achieved US $1.5 billion with over 80% annual growth pace of development. At present, Muyang Group shows the top ranking in global market share in industries such as feed machinery, storage silo, grain machinery, biomass equipments and steel structure building.The sales of Muyang Group in 2015 are estimated to reach US $16 billion.

Top customers

Cargill(US), Charoen Pokphand Group(TH),Bunge(NLD),AB, Agri(UK),CJ(KOR),Watania(KSA), TPS(INA), NSSC(EGY)…

Success Stories

“My

philosophy was to build superior high end products for my customers,

and to do so I knew I needed the best machines. Muyang Group was the

obvious choice.”

Adirek Sripratak – CEO, Agro-Industry & Food Business

“Muyang

Group service is outstanding, and it includes installing, integrating,

servicing and training on advanced manufacturing technologies.”

Armando Emilio Guebuza - Mozambique President

“Our

relationship with Muyang Group is strong and growing. They do what they

say they will do,and their support is everything we expect from our

machine suppliers.”

Christopher White - CEO, Bunge Asia

“You

will not find better local support in this industry than you will find

with Muyang Group.Their Applications Engineers are the best A.E.s I have

come in contact with, ever!”

Obasanjo - Nigeria Former President

Our Modern Plants

|

|

Our Group And International Business

|

|

|

In approximately 100+ countries around the world, you can find Muyang

Muyang Group has eight production bases worldwide (China, Germany, Egypt), four R&D centers (two in China, one in Europe, one in the United States), totally covering areas of more than 1 million square meters with close to 10,000 employees.

|

|

Muyang engineering in the world

Over 5000 referenced feed mills of different kinds in 100 countries

Over 2000 referenced storage projects

Over 1000 referenced steel structure projects

Over 800 referenced turnkey projects for grain process

Certification

Muyang Group has been fully passed ISO9001 international quality system certification and has over 400 national patents, among which are 21 patents of invention and 8 declared international patents. All the core products of feed machinery self-developed by Muyang have passed European CE certification.

|

|

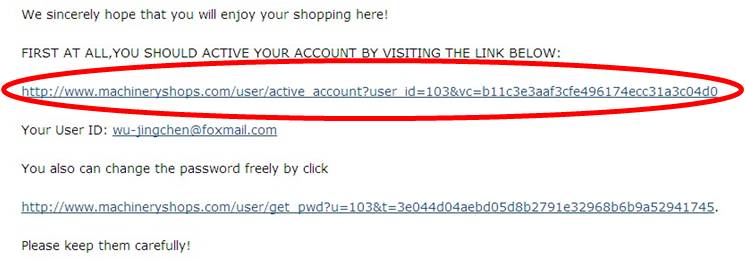

1)Click "Register" button

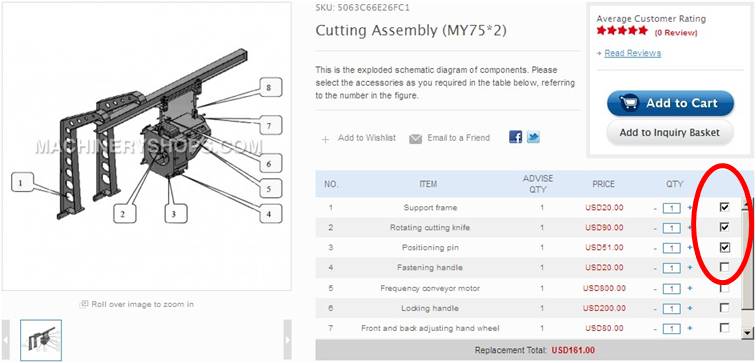

According to the spare parts on display, select the ID number of spare parts you would like to buy, click the “check box” behind ID to record spare parts temporarily.

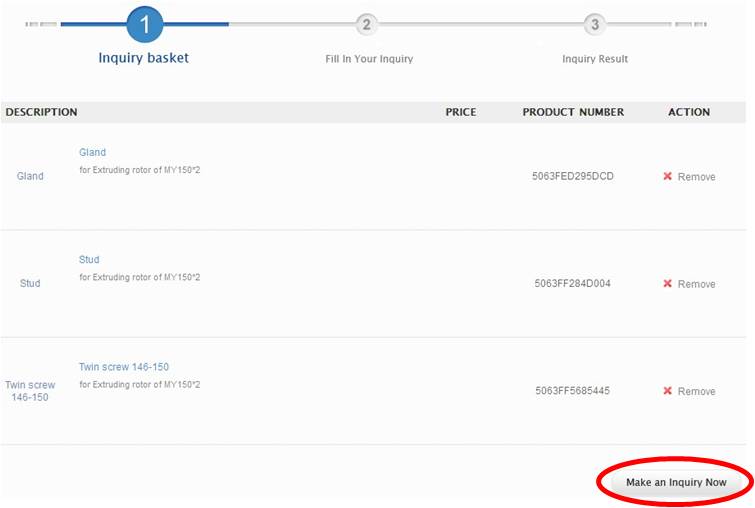

If the commodity you are purchasing has no accurate price, 1)Select spare parts by referring to number in figure, Click “make an inquiry now” button;

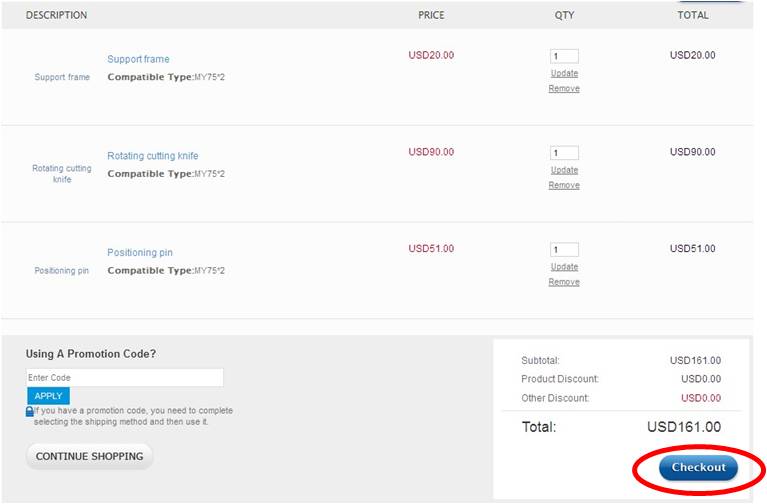

Our staff will provide quotation for you after we verify the orders and automatically help you to complete the purchasing list. If the commodity you are purchasing has accurate price, 3)Click "Add to cart" to add commodity to cart.

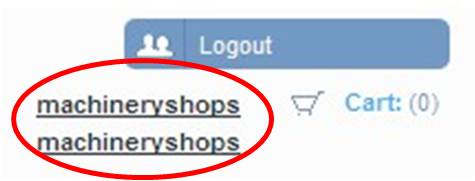

1)After login, click “your account” in upper right corner

5. Order payment:

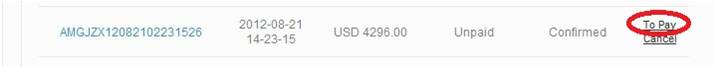

1)You can choose needed logistics way and delivery place when purchasing. 2)Our staff will provide quotation according to your chosen logistics as verifying the orders. You can click "To pay" to check price and payment.

If you have any question about quotation, please contact our staff in time for answers.

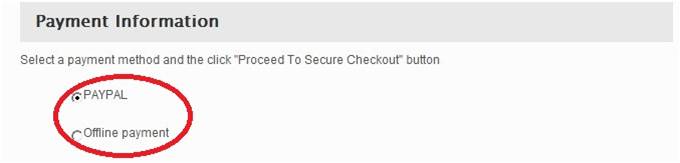

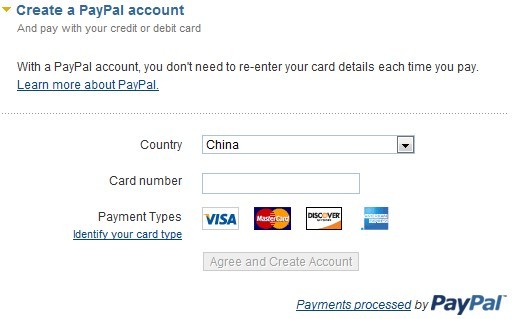

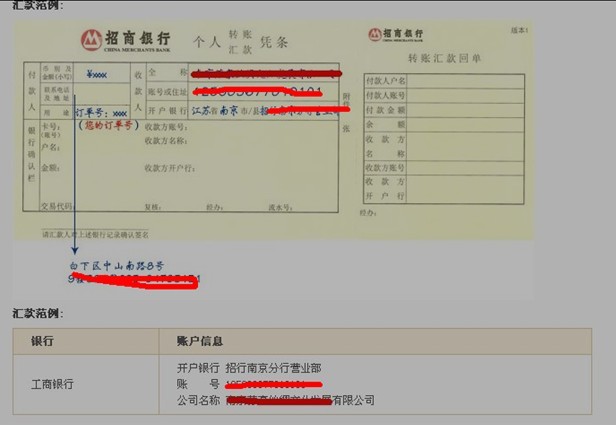

6. Payment methods :

1)We support online PAYPAL payment and offline TT payment. Please inform our staff after finishing the payment.

3)Generally, we default the online order as the contract. If you need a formal contract, please contact us, we will provide you with the formal contact.

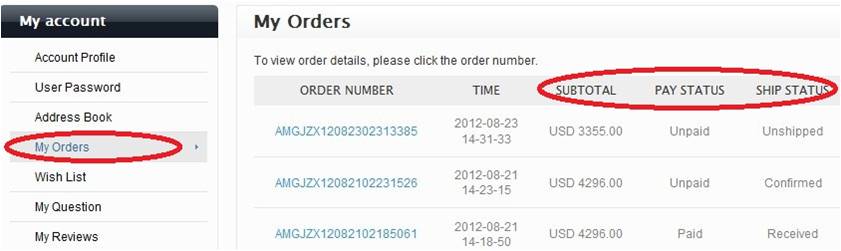

1) Click “My Orders” to check order status; 2) After received products & spare parts you ordered, we really appreciate it if you can rate the service of online purchase from us. We would take your comments and suggestions seriously and improve it promptly. 3) If you need service from us after receiving spare parts, please feel free to contact us online and you will receive attentive and fast service. |

Note: The price in this page is unofficial virtual price. The accurate price will be offered after you place orders

Delivery time:

60-75 days upon receipt of payment, goods leave the warehouse of Muyang

Mode of transportation:

Mode of transportation can be selected according to your demand. In general, sea transportation is recommended. If you are in urgent need, please choose express (recommend DHL). Besides, rail and air transportation are also available.

Package:

We provide packaging suitable for long-distance transport. According to different products, we can provide you with foamed plastic packing, fully sheathed wooden or plywood case with smoked markers, vacuum anti-rust moisture-proof seal aluminizer, wooden pallets, heavy-duty corrugated boxes outside protective packaging. And all the goods are packed by professionals.

|

|

|

Documents:

If you need some documents such as bills of lading, invoice, packing list etc., please feel free to leave your message after you place an order. You can also contact us and we are glad to be at your service.

Country of origin:

The People's Republic of China

Products are manufactured by Jiangsu Muyang Group Co.Ltd., China in year 2012

Acceptance of the goods:

A check on appearance should be made immediately when the accessory is transported to the destination. If it is sure there is any damage caused during transport, a necessary claim procedure must be taken according to the supply contract. The repair expense shall be borne by relevant risk undertaker.

Service

Storage:

The equipment, which cannot be installed in predetermined place immediately, must be stored in a weather-proof place with facilities against external infringement in original packages. Any loss arising from storage shall be conducted as per the contract.

Installation:

The products manufactured by Jiangsu Muyang Group shall be installed only by the trained technical personnel based on installation specifications provided together with the equipment. Muyang Group can provide installation guidance service.