Home>>News

Machineryshops.com

How Extrusion Become Profitable for Piglet Feed

If you have an improved, cheaper and safer end product you will have the edge over competitor and eventually your profit ratio. For feed machinery manufacturing industry, technology that help feed manufactures keep leading in the industry has become the primary consideration for making the investment decision, be it greenfield or upgraded project.For livestock feed production, pretreatment technology is very important, and the basic type of processing used within feed mills usually is pellet conditioner. As concerns over feed cost increased, new pretreatment technologies are asked to widen the scope of available raw materials. And higher standards on feed nutrition and feed safety in breeding farms also require improved technologies and equipment for production, especially for young animal feed. For these reasons, expander used in pretreatment has become more and more popular in processing lines. However, gelatinization level of end product of traditional expander is limited to 60%. When requirement to starch gelatinization comes up to 70~75%, extruder machinery is a better choice than expander, but it also faces problems of reduced output and increased energy consumption .

As a technology problem solver, Muyang introduces a new technology specialized for piglet feed production. The so call “fully extrusion and low-temperature pelleting system” may initially be more expansive than the expander and pelleting system, but when makes a simple comparison of the increased profit from high quality end product and the reduced tonnage power consumption, it can normally be shown to be cost effective, and this is without taking into account the probable increased efficiency of the system itself.

This article will focus on the new system and its application in actual production, in particular.

Fully extrusion and low-temperature pelleting

The lately application of fully extrusion and low-temperature pelleting technology is in the piglet feed production. It is featured by end product of a gelatinization as high as 75% thanks to that all ingredients (except the micro ingredients) have pass through the specially designed extruder for extrusion.

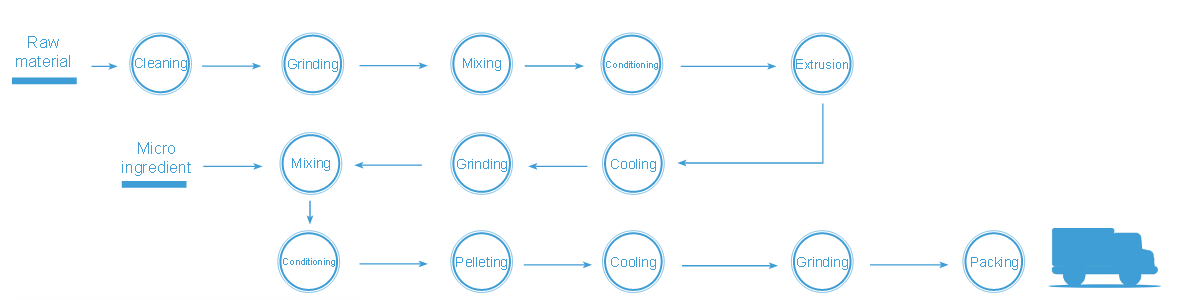

See Fig. 1 Process flow of fully extrusion and low-temperature pelleting line. After first mixing, all macro ingredients are sent to the conditioner for conditioning, and then to the extruder for extrusion. The extruding machine is specially designed according to the characteristics of piglet feed formula. During conditioning and extrusion, the gelatinization of feed mash is increased to 70-75%. Then the extruded products is cooled and ground and then sent to the mixer for the secondary mixing. And micro ingredients in the formula such as heat sensitive, etc. are added to the mixer. After mixing, feed products are treated under low temperature conditioning and pelleting processes. Piglet feed pellets then is cooled and graded, the qualified products finally is packed for delivery.

Special designed extruder

The core equipment of fully extrusion and low-temperature pelleting system is the specially designed extruder. Its running performance will directly impact the production performance of the whole processing line and the quality of end products. In the development of the special extruder (see Fig.2), besides to ensure the target gelatinization for end products, more efforts are invested on how to increase the machine’s output while reduce its tonnage power consumption, i.e. how to increase its energy efficiency.

Feed mash that passing through the extruder is treated under a temperature ranging from 110°C to 150 °C and a pressure scope of 50-70 bar. Accompanying with large amount of energy release from high pressure to atmospheric pressure, flash evaporation of water happens to the extruded products, which contributes to a better texture structure in addition to modified proteins and fully gelatinized starch for end products, bringing better water solubility and improved digestibility performance.

Compared to expander and traditional extruder, the specialized extruder is of following advantages: 1) Processing temperature and pressure scope is higher than expander while lower than traditional extruder, which ensures end products of higher starch gelatinization and better pasteurization for proteinaceous materials when comparing to expander processing, and of higher output and lower power consumption if comparing to traditional extruder; 2) The special screw configuration allows for sectional cooking in the new extruder, which ensures uniform gelatinization of feed mash, and eliminates the loss of heat sensitive ingredients in feed products ; 3) Increased production output and prolong service life of wear parts. It is proved that the wear part cost of the new extruder is as same as that of an expander in practical productions, but the new extruder can save more maintenance work.

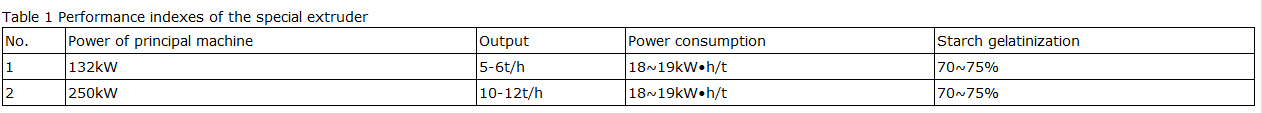

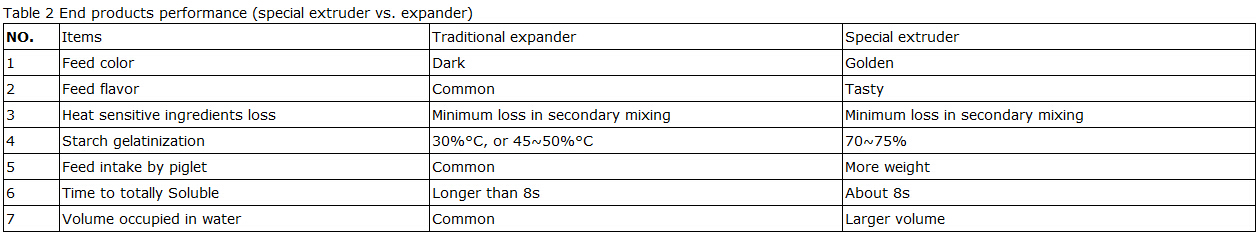

In piglet feed production, when the starch gelatinization is 70-75%, output of the special extruder with a power of 250kW is 12t/h, and the power consumption is 18-19kW•h/t. See Table 1.

Feed intake efficiency comparison

Results of tests demonstrated that piglets fed with feed produced by fully extrusion and low-temperature pelleting line showed significant improvement on feed intake, weight gain and intestinal health. It is because:

1) Fully extrusion process can achieve products tasty flavor and better palatability;

2) Fully extrusion and low temperature pelleting can diminish nutritional ingredients loss during processing, and ensure enough nutrition and energy for weanling pigs, resulting in increased weight gain;

3) Fully extrusion can contribute to higher starch gelatinization and eliminates the effects of anti-nutritional factors and toxins, which is good for intestinal health.

For performance difference details, see Table 2.

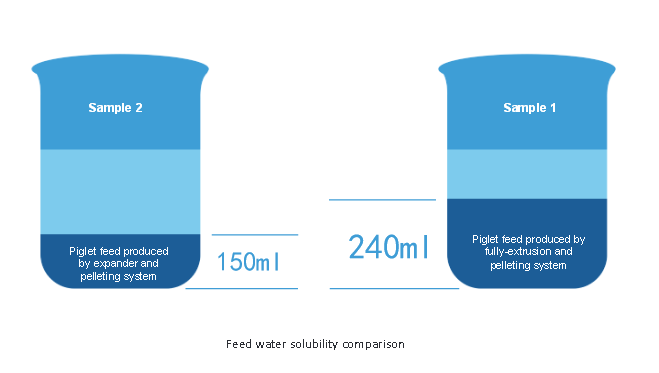

Water solubility comparison

Methodology: The test started with 50g piglet feed (Sample1) from fully extrusion and low-temperature pelleting line and 50g (Sample 2) from expander pelleting line. Prepare two 500ml beakers and each filled with 350ml water. Place the two samples into the beakers separately under a combination condition of room temperature at 20°C and water temperature at 30 °C, and start counting time for water solubility of the two different feeds.

Results: After soaking in the water for 8s, sample 1 is totally soluble in water while sample 2 is started to soluble. After completely soluble, the volume of sample 1 in beaker had expanded to 240ml, while sample 2 only occupied a 150ml volume. Comparison test proved that feed produced by fully extrusion and low-temperature pelleting performs better than traditional expander and pelleting system in water solubility, which brings better digestibility for piglets.

Because of the advantages in feed intake, weight gain and intestinal health performance and production cost, the new technology now has been widely used in greenfiled feed mill and in the upgrade of expander lines in Guangxi Yangxiang, a leading China animal feed producer who is vertically integrated with hog and duck breeding, meat processing and packaged food production.

Conclusion

As the production process within feed mills becomes more sophisticated so the opportunities for cost saving and quality improvement increase. Extrusion processing, to some extent, start to lead a revolution and bring more profit to the livestock feed industry, especially for young newly weaned pigs.

Additional research also underway in Muyang presently to study the application of the new technology in poultry feed and other livestock feed production, and the continued advancements and results will be available in the near future.

Reviews

Write a review

If you would like to write a review, please login first.