Home>>News

Machineryshops.com

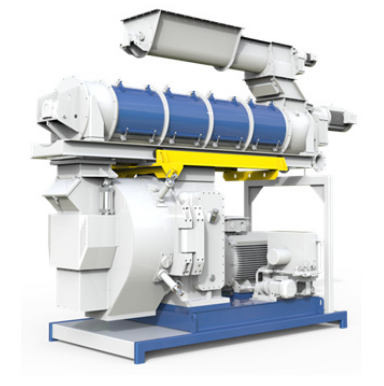

FAMSUN Gear-Drive Pellet Mill

FAMSUN new gear-drive pellet mill debuted at VIV China 2014 on September 24th, the largest and most influential exhibition in the animal husbandry industry. The gear drive pellet mill, the structure and style of which are different from previous pellet mills, is developed Muyang European R&D Institute and features high yield, low energy consumption and high stability.

Advanced technologies and designing concept introduced from America and Europe, combined with rich experiences in product designing, manufacturing, testing, CE certification, enable Muyang European R&D Institute to develop a complete set of research and development system.

FAMSUN gear drive pellet mill is developed to meet the demand of quality and efficiency from livestock and poultry feed pelleting. Driven by a 250 kW motor, the pellet mill SZLH685×245 can produce high quality pellets steadily above 35 tons per hour without downtime. Besides the exhibited model, SZLH575×210 Pellet Mill, which is driven by a 200 kW motor and has a capacity of 25T/H, is also available for this gear drive series to meet different production demands.

Gear drive is more compact, accurate, efficient and has long service life. FAMSUN gear drive pellet mill is equipped with German SEW or American Rexnord gear box and ensures high drive efficiency and low loss from the perspective of processing and installing accuracy. The design of large gear box ensures the stable running during the drive process and restricts the vibration noise within 95 decibel. In addition, the gears and bearings, designed with 1 million hours of operation, ensure long time and stable running of the whole pelleting system and can considerably reduce downtime, maintenance and time cost.

Optimized Structure Design: Large capacity and low energy consumption

The working area and linear velocity of ring die are optimized by the new design. The optimized power per unit area is 15% to 25% higher than that of normal ring die, therefore it has greatly increased capacity output. The size and angle of the optimized feeding scraper enable the material to be evenly fed into the compression area between the ring die and press rollers. The pelleting process is more stable and energy-saving, and the feed products are more evenly distributed. In manufacturing the same swine feed formula, the power consumption per ton feed production of the 35 T/H pellet mill can be reduced to 6.1kW.h/t, 6% to 19% lower than other pellet mills.

CE Standard: Details to ensure safety of man and machine

In years of serving European and American markets, researchers from Muyang European R&D Institute have formed the habit and principle of rendering the CE safety standard and Ergonomic designing concept into the new product. Such factors as the safety of the equipment and operators, the convenience of operation, the safety and health requirement of the working environment are taken into consideration in developing the new FAMSUN pellet machine. All these designing details have ensured man and machine safety, thus improving productivity.

Circumferential clamp ring die installation and unique ring die and press roll replacement tool make convenient replacement possible. Distinct shaft end connection and large space so that the motor doesn’t need to be disassembled in maintenance. The automatic control system based on fuzzy logic can match the process operation and reduce human influence on the production, according to the actual production of the feed plant.

In terms of equipment protection, the overload protection shear pin, power-off protection of the pellet mill access door, gear box oil level monitoring system and gear box cleaning and de-ironing design ensure safe, reliable, continuous and stable running of the equipment.

Strictly following CE safety standard, safety shields are equipped at the observing outlet, air cylinder, coupling, shear pin disc of FAMSUN gear drive pelleting machine. The shields not only prevent dust, but also protect the safety of operators. The safety shield at the outlet can effectively prevent the return of material and steam, and stop the operators from reaching the internal part of the hopper, so that the operators would not be scalded. The safety shield can prevent the broken shear pin from being hurled out and remove potential danger.

Reviews

Write a review

If you would like to write a review, please login first.