Muyang offer complete feed mill construction solutions with advanced technology, efficient equipment, professional installation, complete support and quality service. The daily output of various feed mills Muyang undertook is 100-1,000 tons.

Solutions

Feed mill industry solutions

Muyang is the global leader in feed machinery manufacturing and engineering installation, feed machinery standardization and feed industry technological progress promotion. Muyang export products and solutions to more than 80 countries worldwide.

Muyang provides feed production industry with comprehensive solution of the widest range and the highest level of technology, from a single feed processing machinery and equipment to the entire feed production lines and the new feed mill multi-level comprehensive solutions. For example, for the new feed mill customers, Muyang overall solution include: overall design, plant, steel silo, transportation equipment, feed, machinery equipment, electronic control system, etc., providing users with high-quality, most intimate of "turnkey" engineering services.

Muyang not only provides customers with feed processing equipment and technology, but also provides customers with personalized service, maintenance and training opportunities to help feed factories to run in the most economical way and gain higher benefit and strong competitiveness.

1.Feed production solution design

(1)Determine the scale of feed mill(2)Determine the feed process and recommend equipments

(3)Control mode selection

(4)Plant structure selection

(5)Planning the general drawing of plant site

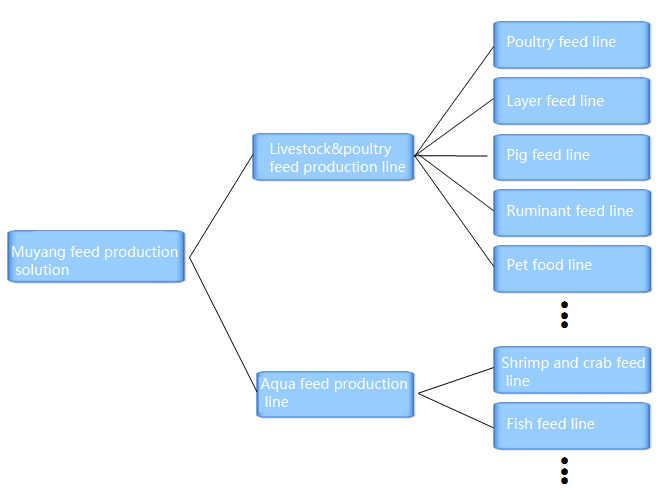

2.Muyang typical feed production line solution

(1) Professional livestock&poultry feed production line

Based on the livestock feed market characteristics, Muyang provides livestock ( pigs ) , poultry ( chicken, duck, goose , etc. ) , and other special animals ( rabbits , foxes , wolves , etc. ) feed production line solutions , Muyang livestock feed production line solutions is on the module design basis and tailored to the particular requirements of clients, fully meeting customers' variety of different feed production requirements along with complying with the most stringent hygiene standards for to produce green, clean , hygienic safety animal feed. Muyang is constantly upgrading technology and process development , in accordance with the safety standards of the European feed manufacturing, providing customers with first-class products and services. Muyang animal feed production process can produce the maximum feed conversion ratio of animal feed, ensuring both the economic interests of feed manufacturer and the health of animals, so the green safety of the food chain downstream products is guaranteed. For a long time, Muyang possesses the most advanced technology in manufacturing technologies of feed machinery industry and integrates them into products and projects.

Muyang solutions feature great flexibility and customizability. According to customer different feed types, different output configuration can be customized. For instance, Muyang livestock and poultry feed production solutions applicable for the following general customer needs:

a chicken feed production line: 3 to 40 TPH

a duck feed production line: 2 to 35 TPH

…….

For those customers whose capacity does not list in the above production line range, Muyang can makeailored solutions for customers to meet their special requirements.

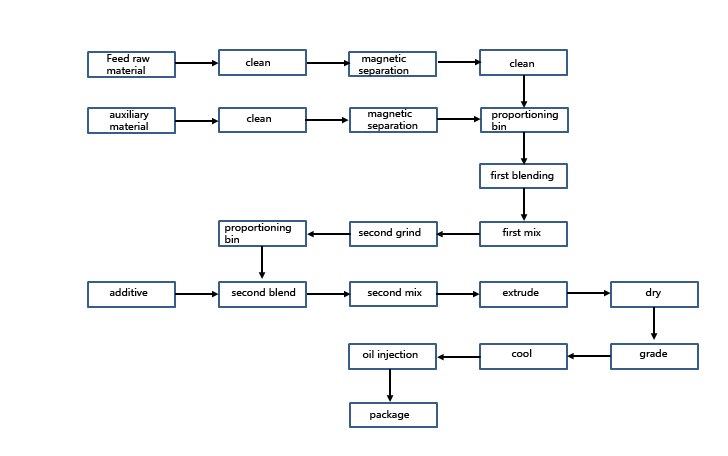

(2) Agua feed production line

Muyang leading aquatic animals (fish, shrimp, crab, etc.) feed production line solutions meet customer's individual line from 0.5 to 30 tons per hour production needs.

How to choose a high-quality, low-cost, high-grade fish feed, fish feed production process technology program? It lies in the production process. As technology and market leader in the industry, Muyang knows that in aquatic feed production process, in addition to reasonable formula, a very important point is that the process must be gentle to prolong the feed in the water-soluble, which is very important to aquatic animal health and growth. Muyang has the most experienced design engineers, reasonable recommendation, diversified technology production line design.

How to choose right crushing equipment and optimized mesh system to improve grinding efficiency, reduce energy consumption? Muyang has the world's top grinding technology for customers to build high-value, low-power type crushing system.

Muyang extruding process uses fully automatic extruding process, automatically microcomputer steam added technology, precise control of the sinking and floating material; computer conditioning control, "tiptronic" better control the degree of maturation, improving the ripening degree and digestion and absorption rate. Cooking or curing molding extrusion and molding granulation process, pre-conditioning process and final conditioning process altogether determine the characteristics of the final product. Muyang provides customers with the best technology and products to help customers get high-quality aquatic feeds.

With Muyang extruding and pelleting technology, customers can minimize costs while ensure optimal product quality and maximize revenue. Meanwhile, customer can produce ideal feed of maximum digestibility and feed conversion ratio, so the overall health is guaranteed.

(3) Ruminant feed production line

Based on the ruminant feed market characteristics, Muyang provides a full range of ruminants (cattle, sheep, etc.) animal feed production solutions and turnkey projects, Muyang ruminant feed production line solutions meet customers 5 to 45 tons per hour production needs.

Muyang has the world's advanced cattle and other ruminant animal feed processing technology, according to the ruminant digestive physiology unique characteristics and nutritional requirements of cattle and pig feed, poultry feed and feed in the feed formulation process is very different modulation. Muyang can provide customers according to their tailored demand with the most suitable processing technology and equipment. Muyang equipment of efficient and reliable production contain a patented technology, which can minimize the production of contamination and cross-contamination, and achieve traceability throughout the production process.

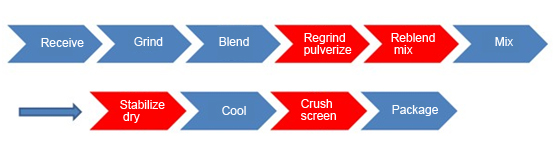

(4) Premix feed production line

Muyang premix feed production line solutions meet customers 1 to 45 tons per hour production needs with turnkey service.

Muyang not only provide customers with pre-mixed feed processing equipment and technology, but also provide customers with a full range of personalized services to help feed factories to run in the most economical way, bringing to them higher benefit and strong competitiveness.

Muyang pre-mix feed production solution has the following unique advantages:

High precision micro-component proportioning system, ensuring that the ingredients of various trace elements, measurement precision. Customers can add a variety of trace elements, drugs, improve animal disease prevention, disease resistance;Dedicated equipped with efficient "hybrid king", mixing speed, high uniformity, low residue, CV ≤ 1%, ensuring mixing precision;

Unique injection device is equipped, minimally reducing residual materials;

Professional premix production, one large and one small mixer using process configuration, according to the premix varieties recommended rationalize production, reducing energy waste and production costs;

Carrier ingredients, using a dedicated bin, strict procedures, preventing cross-contamination of ingredients;

after blending , the material is conveyed by positive pressure pneumatic, abandoning the traditional mechanical transmission, greatly reducing the residual refuse cross-contamination, which contributes to clean, hygienic and safe transport effects;

Reasonable and effective dust removal system, all the material inlet and outlet are equipped with centralized dust pulses, thus reducing dust pollution and dust will be strictly controlled by the state below standard.

(5) Pet food production line

Muyang pet food production line solutions meet customers' individual lines from 0.1 to 15 tons per hour production needs, providing turnkey engineering services.

Pets are man's best friend. High-quality pet food not only attracts animals in appearance, but is infinitely delicious and healthy as well. But only the advanced production technology and processes can achieve this production standard. Muyang extruding process is cost-effective, reliable with gentle processing techniques and is the best choice for pet food producers.

perfect the production of pet food, according to customer requirements flexibly adjust product formulations size, shape, and moisture content, and in accordance with the requirements of coloring, flavoring and add various powder ingredients;

Muyang extruding process strictly oriented to customer value, automatic extruding process, automatically microcomputer steam added technology, precise control of sinking and floating material;

Conditioning computer controlled "tiptronic" better control of the degree of curing, curing degree and improve digestion and absorption rate;

System conditioning pellets sterilization using oxygen, can effectively kill all bacteria, improve the quality of feed, while maintaining the valid lifetime vitamins;

A full range of technical support services, recommended micro-grinding and ultrafine grinding equipment, reasonable control of grinding fineness suitable both for pet food needs and rational use of energy;

variety airless spray equipment, leading technology, quality assurance finished materials; Muyang goal is to produce a higher quality pet foods and minimize production costs and maximize benefits.

3.Main equipments

(1) For Large livestock&poultry feed plant to choose

first choice to buy for global top 50 feed producers

represent the highest technology level in industry

same power, higher capacity

more stable, longer life

same investment, higher benefit

……..

Muyang Double-circle Mixer

|

Muyang doule-circle mixer volume:0.2m³、0.5m³、1m³、2m³、3m³、4m³、6m³、8m³ eight specifications. |

Leading advantages:

International patent double rotor design, inside and outside the double-blade design enhancements material convection, shearing, mixing, mixing uniformity up to 97.7%.blade and chassis an optimal gap, ensuring residual rate of ≤ 0.1%, avoiding cross-contamination of materials;

Full-open discharge door, instantly emptying the material, no residue

discharge door using silicone seals, ensuring no leakage, and long life; Shaft using a specially designed packing seal, ensuring no leakage.

Muyang"SLHSJ"serie double-shaft efficient mixer

-essential equipment for agua feed and premix feed plant!

|

Muyang doule-shaft efficient mixer volume 0.1m³、0.2m³、0.5m³、1 m³、2m³、3m³、4m³、7m³、8m³、10m³ ten specifications |

Leading advantages:

Wide application

Applicable material mixing a variety of industries, the effective volume of the body large; You can add a variety of liquid (such as: water, molasses, oil, etc.).

Good quality equipment

Smooth, gentle mixing, no damage of material original characteristics.

High efficiecy

Short mixing time (45 ~ 60 seconds / batch), blending uniformity coefficient of variation (cv) less than 3%, less power consumption.

Less residue

Original "drive bays full length double-door" patented technology, the material quickly, the maximum possible reduction of residues.

compound grinding chamber

Effectively destroy circulation, promote convection material layer, thereby improving the efficiency of grinding and the sieve, improving production.

crushing mode oflow power consumption

New tooth plate structure, improve crushing methods, increasing the crushing effect of friction, improving energy efficiency, reducing the crushing power never.

high-precision balancing rotor

Stable and reliable equipment operation, prolonging using life.

Humanized operation

Shift operation can be fully open doors and hammer replacement auxiliary structure, operation, maintenance and replacement hammer more convenient time-saving.

Muyang Pulverizer

|

High capacity, low power consumption, super stable running

|

Muyang twin-screw extruder

|

High torque, high speed, high pressure Basic modular structure, the combination of the individual modules, meeting customer-specific applications, providing the best tailored extrusion system. |

(2) Essential equipment for medium and small-sized livestock&poultry feed plant

Muyang 350 serie pellet mill

|

Superstable running,Surging power transmission

Meet production needs |

Leading advantages:

manufacture in accordance with international standards of advanced technology

advanced dual-stage drive system, stable and reliable performance, low noise;

key parts are imported, long life, low maintenance costs;

spindle alloy steel forging, high durability and good toughness;

equipped with semi-automatic oil adding equipment to facilitate lubrication;

widely used for high quality poultry feed, aquatic feed, compound fertilizer and other materials granulation.

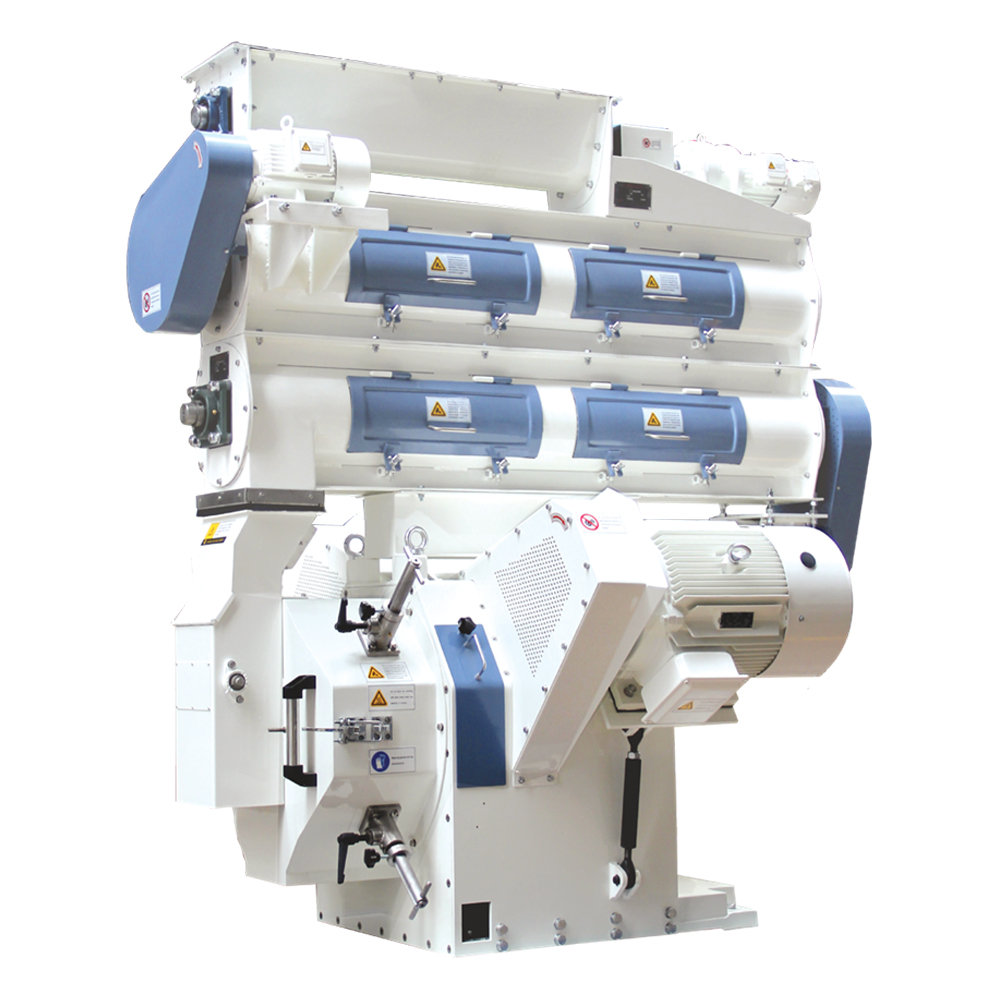

Muyang MUZL420TW(V4)Pellet Mill

|

Meet production needs Poultry feed:12-14t/h Chicken feed:10-13t/h |

High capacity

Muyang "Jin Chi" V4 new particle machine (55kw * 2), production of chicken feed, 3.0mm aperture ring die, production up to 13t / h or more.

Low cost

Belt drive for routine, maintenance costs are very low, compared with the gear box, no requirement of lubrication and easy maintenance.

super stable

The most popular use of international dual-motor synchronous drive, dual-motor drive is the preferred way to Europe and other developed countries, the unique stable belt type transmission, more secure and stable.

Humane

A variable frequency motor feeding, overload protection device, outboard discharging mechanism, the necessary security settings, the use of more safe and secure.

4.Why choose Muyang solutions?

(1) Good brand

International company, global operations in more than 100 countries and regions, with annual sales of $ 2 billion, industry leader, won deep trust of customers.

(2) Good reputation

Most of top 50 feed producer is Muyang's long-term customer

— Jingzhou Haida Feed Co. 2012-12-25

(3) Good product

a Take the lead of highest technology of the industry

Possess Nanjing, Germany, the U.S. Institute, the introduction of first-class team of experts in Europe and America, leading the industry's highest level of technology;

hire top talent in the global research and development, such as the Kansas State University professor and expert on Japanese technology pellet mill and other major models to optimize the design and research;

global leader in feed machinery industry standards

the only "national post-doctoral research station" in the industry

pass through the most authority of the certification in the industry

Intelligent painted lines

(4)Good service

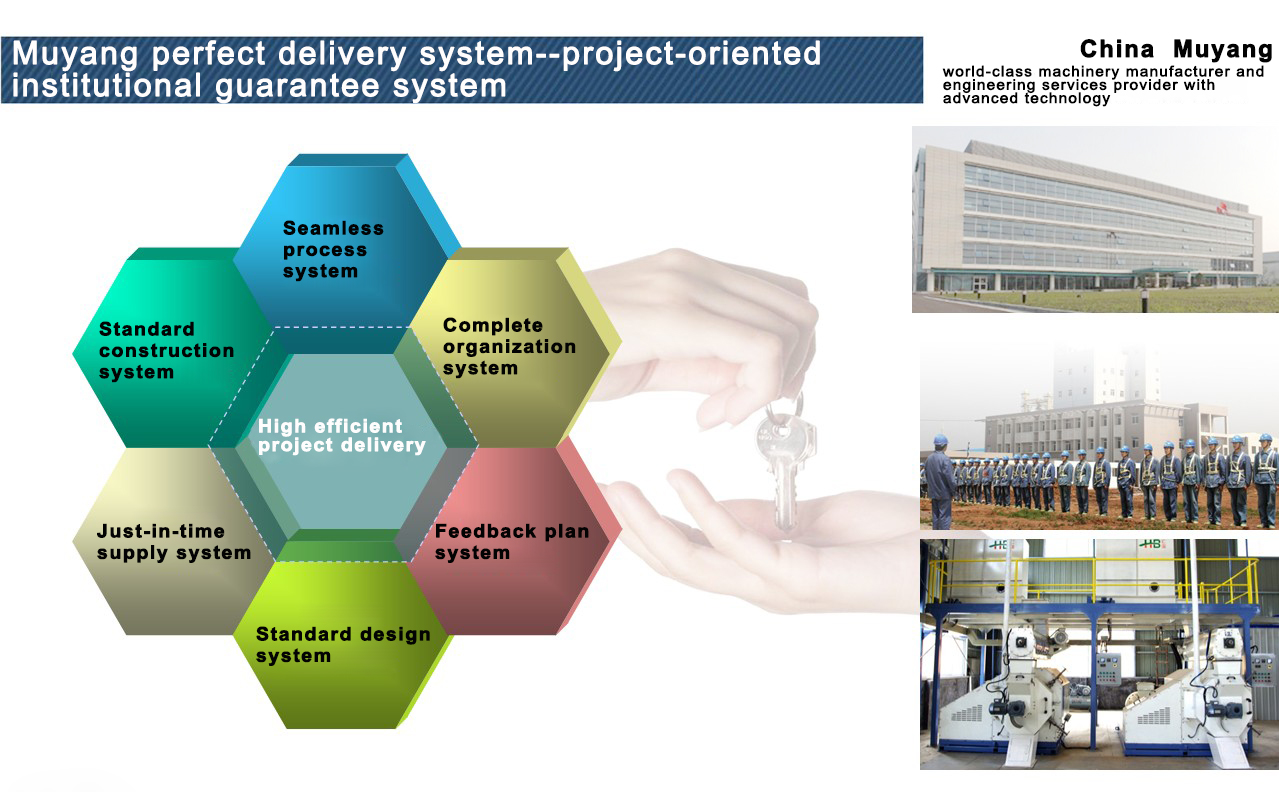

a Muyang perfect delivery system

b Gold service

Currently Muyang marketing and service network cover around the world in more than 80 countries and regions with branches or offices. Muyang has a strong localized sales and service teams, providing global customers with localized pre-sales consulting, solution design, product customization, project implementation, equipment installation, maintenance, warranty and all other services.

Above solutions have been successfully applied to the world's leading feed production enterprises as follows: